- Products

- SolidScape

- Machines

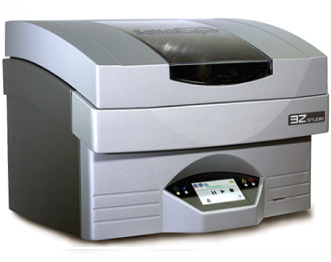

SolidScape 3Z Studio

From Inspiration to Finished Design

The Solidscape® Studio brings the jeweler's bench to the retail shop where users of any technical level can produce their own intricate wax patterns, ready for casting. The fully automated Studio marries the passion of fine jewelry design with the power of high precision 3D printing.

Easy One-Touch Operation

Intuitive one-touch operation via a universal LCD icon display eliminates language and technical barriers.

Efficient Workflow

The Studio empowers the jewelry creation process from design through finished wax patterns in an effortless workflow that delivers high casting yields, consistent turnarounds and low cost-per-parts.

Superior Casting Results

New Solidscape® Model and Solidscape® Support materials produce extremely smooth jewelry wax patterns that accurately reproduce the most intricate of geometries?without the need for manual refining. Both materials offer superior casting properties, fast meltout, no ash or residue, and no thermal expansion.

Fully Automated |

Self installation |

Automatic job set-up |

|

|

|

Accessible |

Icon-based user interface |

|

Files, job start-up and job status can be managed and viewed remotely from PC |

|

|

Resolution |

5000 X 5000 dots/inch (197 X 197 dots/mm) in X, Y |

8000 dots/inch (315 dots/mm) in Z |

|

|

|

Accuracy |

± 0.0010 inch/inch (±25.4µ/25.4mm) along each axis X, Y and Z |

|

|

Layer Thickness |

User selectable through variable slider |

|

|

Surface Finish |

Layer thickness dependant, up to 32 micro-inches (RMS) |

21.4" W X 18"D X 16" H (558mm X 495mm X 419 mm) |

|

|

|

Weight |

75 lbs. weight (34 kg) |

|

|

Build Envelope |

6" X 6" X 2" (152.4 X 152.4 X 50.8 mm) |

|

X, Y, Z Consistent results over entire 6 inch x 6 inch (152.4mmx152.4mm) area |

|

|

Power Requirements |

90-250-v, 10A @ 230v max consumption |

|

|

Ambient Operating Temp |

Recommend 60° to 80° F (16° to 27° C) at a 40% to 60% range of humidity |

|

|

Equipment Interface |

PC to printer connectivity |

|

Hi-Speed USB 2.0 |

Model material formulated for clean burnout to produce 100% castings |

|

|

|

3Z?Support |

Sacrificial material generated automatically for each job, and later dissolved away for a labor-saving, hands-free operation. |

|

|

Dewax |

Liquid solution used to dissolve sacrificial material |

|

|

CAD file input |

.stl and .slc files |

|

|

3Z?Works |

Software that formats CAD files for 3D printing |

|

Allows operator to visually place job suites within build envelope |

|

Automatically generates sacrificial support structure, saving design time |

|

|

3Z?Touch |

System Software is Windows® based |

|

|

Automatic |

Status monitoring and fault detection |

|

Re-start of build from point of interruption |

|

Works unattended up to 72 hours |

|

|

SCP® |

Smooth Curvature Printing for superior surface finish |

|

|

CE certified; FCC Class A approved |

TUV approved (EN 60950 Compliant) |