- Products

- Concept Laser

- Concept Laser Applications

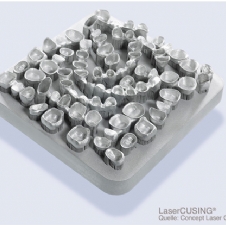

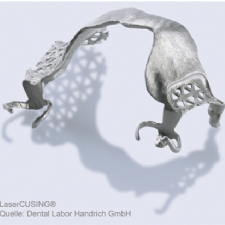

LaserCUSING® is revolutionising the dental industry

The generative metal laser melting process is used to manufacture dental products such as crowns, caps, model castings and secondary structures in an economical way. On account of the standardised production process, unique specimens or small batches can be manufactured with a constantly high level of quality.

High-quality, perfectly fitting dentures made from cobalt-chromium, titanium or precious-metal alloys ? virtually overnight!

The DENTAURUM Group, which leads the way in the field of precious-metal-free dental alloys, is our partner and produces exclusive powder materials for processing using the LaserCUSING® method which are available exclusively to Concept Laser customers.

Two patented and clinically proven precious-metal-free alloys which were previously available as an alloy in the form of cast cylinders and as a milling blank are now exclusively also available to procure as a laser fusable powder material through Concept Laser:

remanium® star CL

rematitan® CL

The products which are produced using the LaserCUSING® method meet the requirements of the German Medical Devices Act (DIN EN ISO 9693 / DIN EN ISO 22674).