- Products

- Lithoz

Lithoz Applications

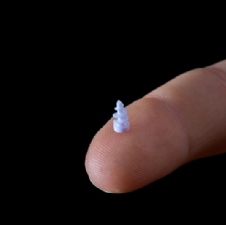

Prototypes for Powder Injection Molding

Lithoz enables the fabrication of prototypes without any costs for tools while achieving the mechanical characteristics of serially produced parts

Requirements for high-quality prototypes

The fabrication of functional prototypes usually poses a great challenge for companies. It is often necessary to provide parts for testing purposes before beginning with mass production. These first prototypes have to comply with the serial component in terms of geometry, functionality and mechanical properties in order to convince the customer of the product. Lithoz offers the possibility to produce prototypes which meet these high standards.

Cost-efficient prototypes

Lithoz is the first company to offer a process for the economic fabrication of ceramic prototypes. Without the need for the production of expensive tools it enables the fast and uncomplicated manufacturing of arbitrary geometries in a single work cycle. This method not only guarantees the same properties as for serial components, it also provides more flexibility and significant savings in costs and time for the prototype production. Using this approach, it is possible to shorten the time-to-market substantially.

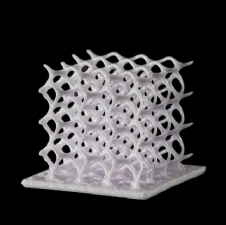

Same material as in serial production

The LCM (Lithography-based Ceramic Manufacturing)- process developed by Lithoz not only uses the same material as the serial production, it also ensures that precision, density and strength of the part can be guaranteed. Where other prototyping techniques such as hot pressing, milling or other additive manufacturing processes have failed, the Lithoz LCM-process successfully produces high quality ceramic components.

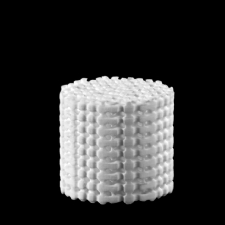

The advantages at one glance:

- Lot size 1

- Material properties as in serial production

- Exceptional surface quality

- No tooling costs

- Arbitrary geometrical variations

- No costs for design changes

- Direct production from the CAD-data